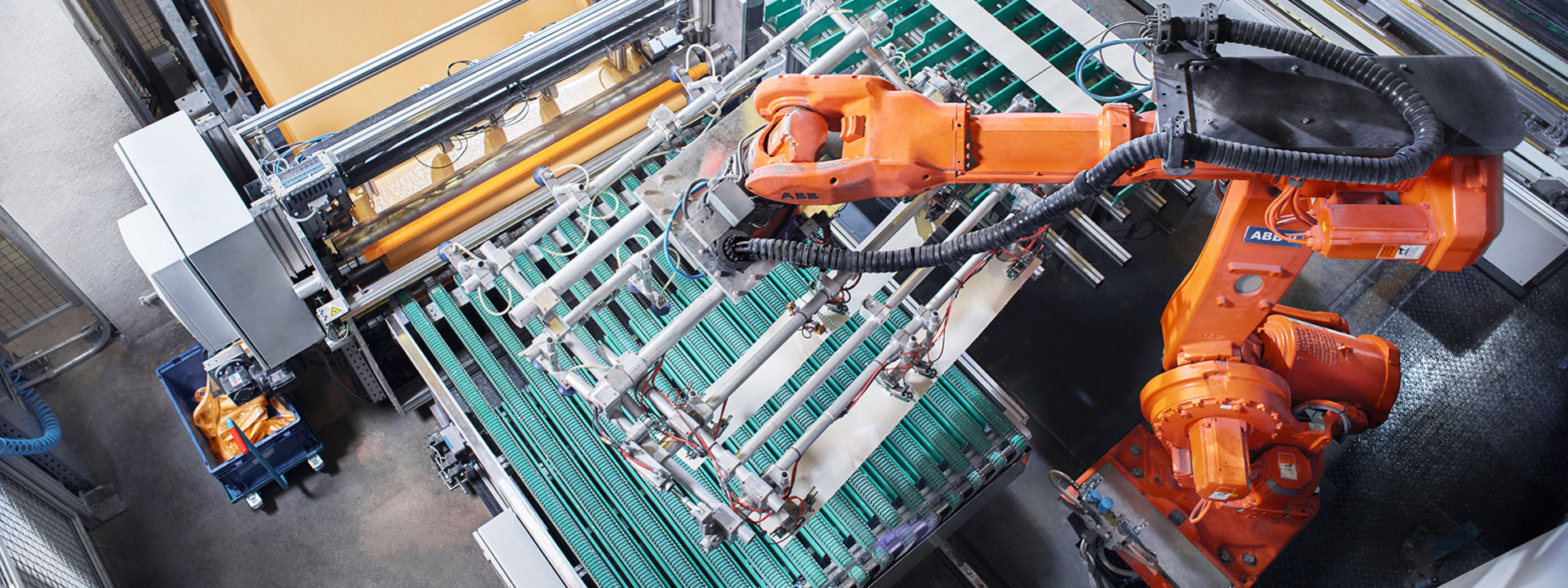

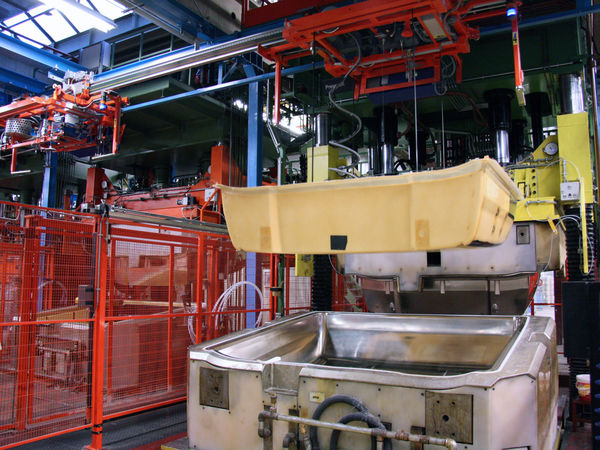

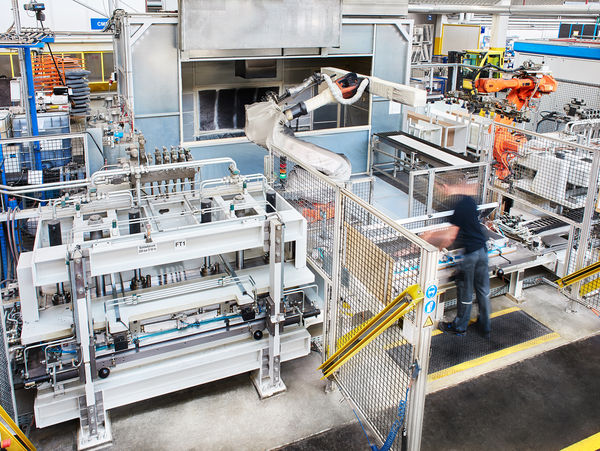

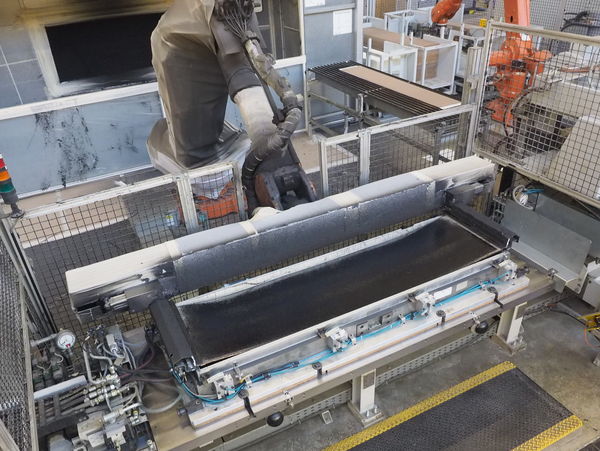

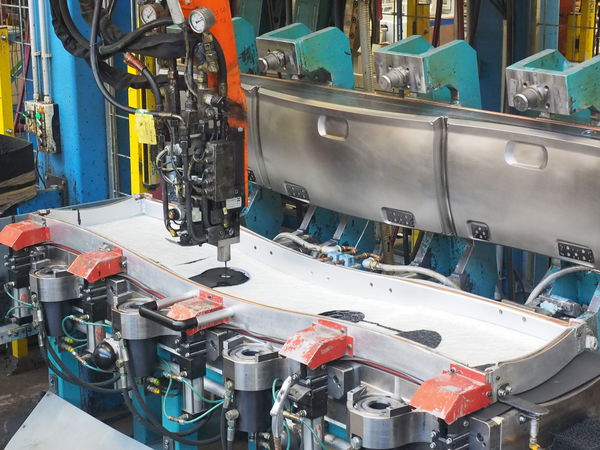

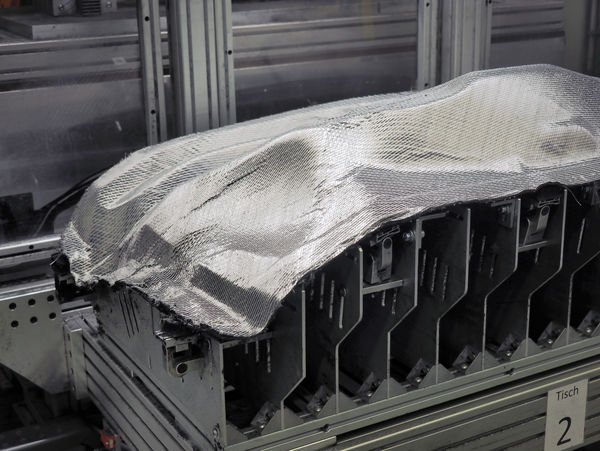

Resistance to chemical agents and temperature changes, high dimensional stability and Class A surface quality characterize components made with SMC. Fritzmeier masters the whole SMC technology spectrum and uses it to make components for trucks, cars and agricultural machines. The production options include direct coating processes like IMC (In-Mould Coating) or IPC (In-Mould Powder Coating), as well as the online bonding of 2-shell thin foil parts.

Sample products:

Wind deflectors, front hatches, rear hatches, tractor roofs